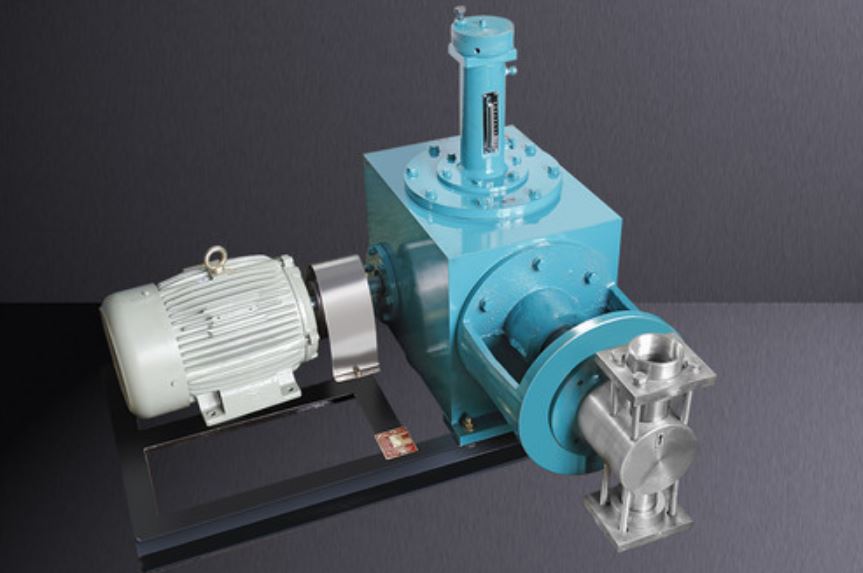

Installing metering pumps is an incredibly important and necessary task. However, it requires the right skill and expertise to maintain the water system properly. A metering pump measures the quantity of a liquid during one inflow and ejects a calibrated amount from the outlet valve at regular intervals.

This flow rate is then converted into units of cubic meters per hour by mechanical meter dials that are automatically or manually adjusted according to changes in water demand. There are many factors to consider when installing metering pumps, as these play a vital role in the maintenance and lifespan of the equipment. Here are some of them:

1. Flow Rate

The flow rate is a key consideration when choosing a metering pump and mechanical meter dials. The flow rate is directly proportional to the size of the pump, so it becomes necessary to determine how large a pump you will need based on the amount of water that needs to be pumped and how much time it takes for one cycle. For example, if a household is under a quarterly allocation of 60 cubic meters per hour, it should purchase a 120 cubic meter per hour pump. However, if the same household has been allocated 120 cubic meters per hour and wants it every fortnight, it should purchase a 30 cubic meter per hour pump for the period.

2. Pumps vs. Metering

Pumps are designed to be used with mechanical meter dials to measure flow rates, while metering pumps, on the other hand, do not require mechanical meter dials. The operation of metering pumps is based on the principle of a fixed-displacement pump. A metering pump has a cylinder and piston with a fixed displacement for each stroke that is carefully fitted within the pump body.

When water passes through the unit, it will have to displace some of it from the outlet hose, increasing pressure. At this point, the piston will move up and down in the cylinder to generate a calibrated flow rate. The metering pump can be easily installed in the system because it has no moving parts that could cause problems.

3. Tolerance

Tolerance is another important consideration when installing mechanical meter dials on metering pumps. These dials should be designed using a high-precision component because these components are responsible for converting the flow rate into units of cubic meters per hour as per the approved specifications.

4. Storage Capacity

Before purchasing a pump, one should assess the storage capacity of the system as well as groundwater levels in the area where it will be installed. A pump with a larger capacity should be considered if the system can take more volume of water at a time. Furthermore, the height of the groundwater level and its proximity to surface water levels must also be considered to choose appropriate pumps with enough flow rates for the system.

5. Installation Height.

The required length of pipe between the meter and its outlet valve should be calculated before buying any pumps. The distance must be based on the required head loss to accommodate any defects in the piping or connections within the system. This will ensure an accurate reading on the mechanical meter dials.

6. Maintenance

The metering pump should be checked and maintained regularly, especially during the first few months of operation. This is because it takes a period for components to adjust themselves in the system, and therefore minor adjustments may be needed. For example, if running too slow, the pump may need to be adjusted after about three months. The meter dials should also be regularly checked for signs of wear and tear, such as fraying around the edges or rusting on metal parts due to regular exposure to water.

7. Energy component

The energy component is another important consideration when choosing a metering pump. The energy component is a valuable source used to convert the flow rate of water pumped into units of cubic meters per hour. To estimate the energy component, the flow rate of the water pump can be divided by the time taken for one cycle by mechanical meter dials. The resulting unit of measure will be kWh/day or kWh/hour (kWh/day = 1m³/h).

8. Protection from Pollution

The pump should be designed to resist corrosion and erosion from water exposure and other compounds. This is because the mechanical meter dials are directly linked to the pump, so they will also be prone to corrosion if the pump is not resistant.

Are you considering the installation of a metering pump? If so, get your metering pumps to from us for reliable and trustworthy service. We have many years of experience in this field, so we guarantee our services. Get your Metering Pumps in Saudia Arab from Ejawda.